G3 Welcomes Visit From Engineers’ Club Group

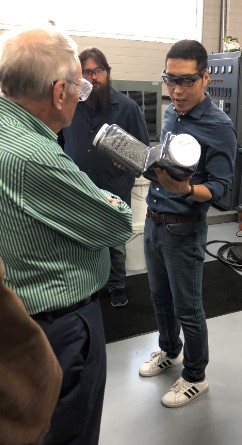

Global Graphene Group welcomed 16 members of the Dayton Engineers’ Club’s Barn Gang to our Dayton facilities yesterday afternoon. The Barn Gang is comprised of retired engineers, and they meet regularly to tour area companies. G3’s John Davis, Dr. Aruna Zhamu and Stuart Blair presented to the group about what graphene is, it’s trajectory in commercialization and Global Graphene Group at a high level.

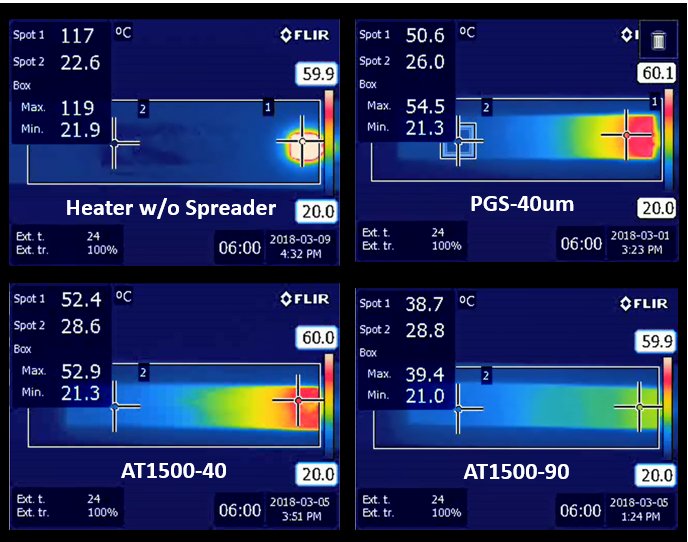

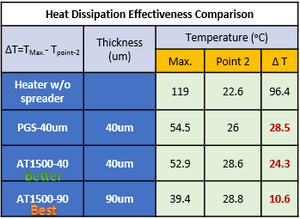

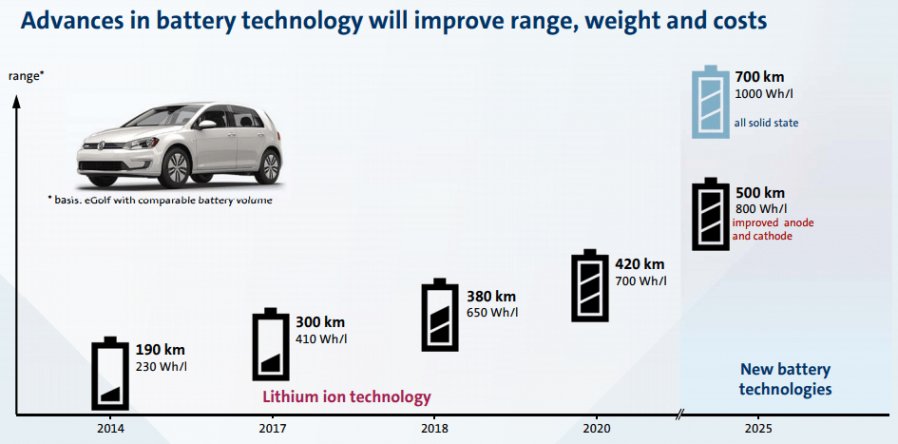

The Barn Gang was full of great questions and were very interested in graphene’s potential applications. The group toured our thermal labs and discussed our thermal film production both here in Dayton and in Taiwan. The group learned about our graphene-silicon anode production and our plans to increase it in 2020.

G3’s experts discussed our masterbatches and composites, showing off the graphene-infused ECD lacrosse heads we produced last year. The group toured our Quality Lab and discussed our recent ISO re-certification. We finished the tour with a walk through our battery prototyping center and 3,000 square feet of dry rooms.

“Global Graphene Group was proud to host the Engineers’ Club Barn Gang,” said Dr. Aruna Zhamu, G3 co-founder. “Considering Dayton’s history of innovation in engineering, the Barn Gang was very interested in graphene’s applications and how it will change the world.”

“We were excited to welcome the Barn Gang to our Dayton facilities,” said John Davis, G3 COO. “Today’s tour is a great example of sharing the story of graphene and our company with the Dayton area. We are committed to expanding in the Dayton region as we continue to ramp up our commercial production.”