This year has not turned out the way most everyone imagined it would from the start. No one could have predicted that we’d be in the middle of a worldwide pandemic. Despite the challenges that 2020 presented, the team at Global Graphene Group is ending 2020 on a high note. Graphene is part of the global conversation now more than ever before. And G3 is prepared to provide our solutions and technology to help improve lives.

To help fight the global pandemic, G3 is currently working with a company to produce PPE masks using our graphene solutions. Graphene is known for its anti-microbial and anti-viral properties. Researchers have incorporated graphene into N-95 masks, essential PPE for healthcare workers and others. This added layer of protection has shown to provide up to 99% effectiveness at blocking the COVID-19 virus.

G3 continues to work with a leading Fortune 75 company to incorporate graphene into their products. G3’s graphene oxide dispersion has shown to improve nylon tensile strength by as much as 400% in the similar markets. We’re looking forward to commercializing our efforts with this company in 2021.

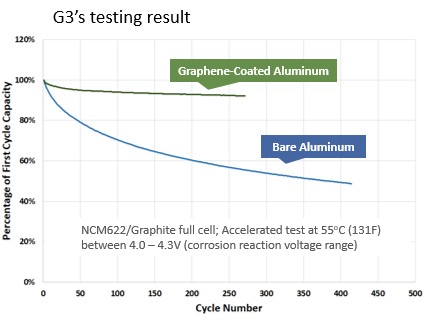

G3 is also working on our graphene-enhanced coatings for several key industries. Adding a small weight percentage of graphene to paints and coatings can reduce the amount of material needed to coat a structure by more than 40%, while adding significant anti-corrosion properties. This will decrease the costs of coatings for companies and extend the life of the coating.

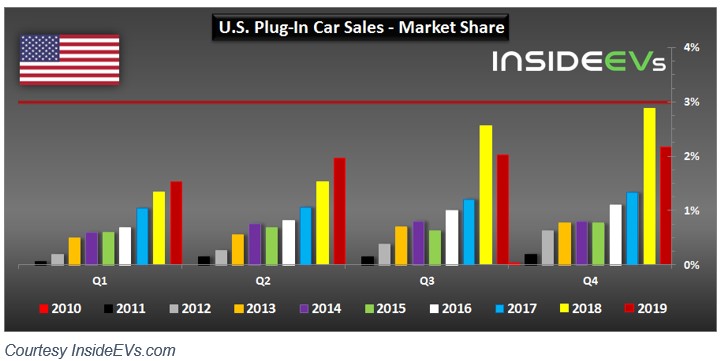

Many areas of the world have pushed for EV adoption in the next few years, making EV OEMs look for ways to increase battery energy density and safety, ramp up the mileage per charge and decrease production costs. One top-tier OEM announced its intention to use a specific anode technology using elastic polymers, which G3 owns the IP for.

Industry-leading EV OEMs indicate elastic and ion-conducting polymer-encapsulated Si technology will be needed to drive EV battery technology that will lower cost and provide higher energy density, extending the EV driving range by 20%. G3’s innovative Si anodes can deliver this and more today as a drop-in technology. Furthermore, G3’s entire suite of battery-enabling technologies can deliver driving range improvements of 50-100% at significant cost savings. G3 is working with several top-tier EV OEMs to validate our EV battery solutions and we look to increase production of our Si anode solution in 2021.

Our G3 team is growing to keep up with the demand for our solutions! We’re looking for battery scientists, technicians and an experienced production manager. If you are looking for a challenging, exciting role with an expanding company focused on the next generation technology in multiple industries, apply today!

2021 looks to be very bright for graphene as more and more people are realizing its sustainable properties and the value it brings. G3 is poised to support a variety of companies to incorporate our graphene technology and solutions into their products in 2021 and beyond. If you’d like to discuss how graphene could help your company, drop us an email.